Cutting – Projects

We analyze your cutting tasks and offer you a profitability comparison between thermal cutting processes. Furthermore, by using our cutting process, we offer feasibility analyses and preliminary tests of your individual cutting tasks from fiber composite materials to highalloy thick sheet metal, and upon request, we also offer preliminary studies for plant networking and integration in your IOT / I4.0 environment.

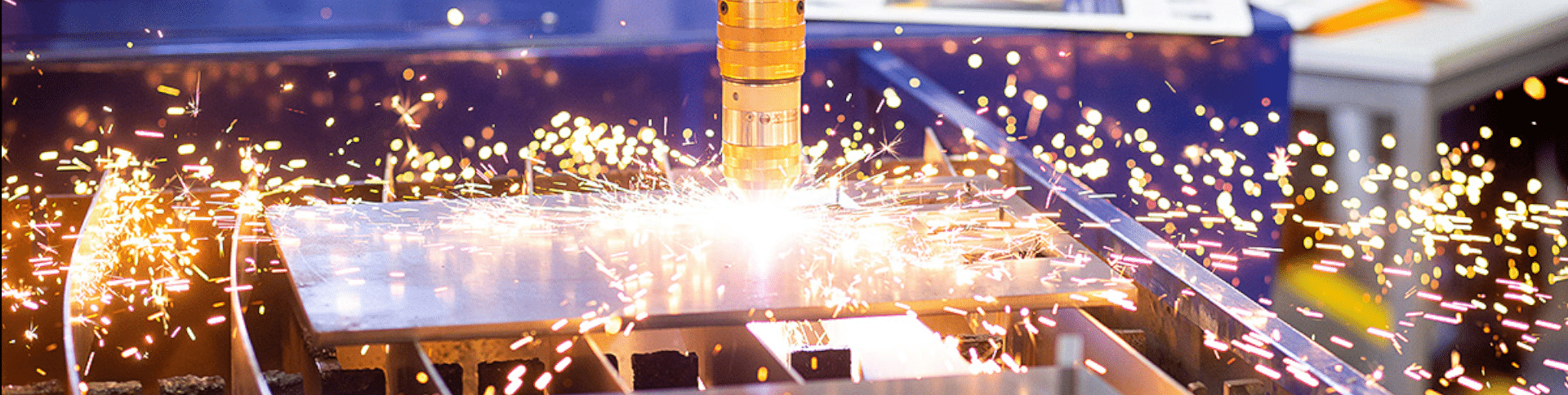

In plasma cutting, an extremely focused plasma jet with a temperature of up to 30,000 K and a speed of 1000s m/s is used to melt the material locally and drive it out to form a kerf. Kjellberg Finsterwalde has already realized this in the best possible way: The plant technology achieves maximum productivity and laser-cut-like, nearly post-processing-free cutting edges of sheet thicknesses between 1 and 150 mm.

Laser cutting is a thermal cutting process for electrically conductive and non-conductive as well as combustible and non-combustible materials by means of a laser beam. The process is particularly used where complex contours are to be cut precisely and quickly, preferably in the lower sheet thickness range of up to 10 mm and where particularly high quality requirements are in place (shape deviations in the contour area)