Profocus

3D shaping with different materials

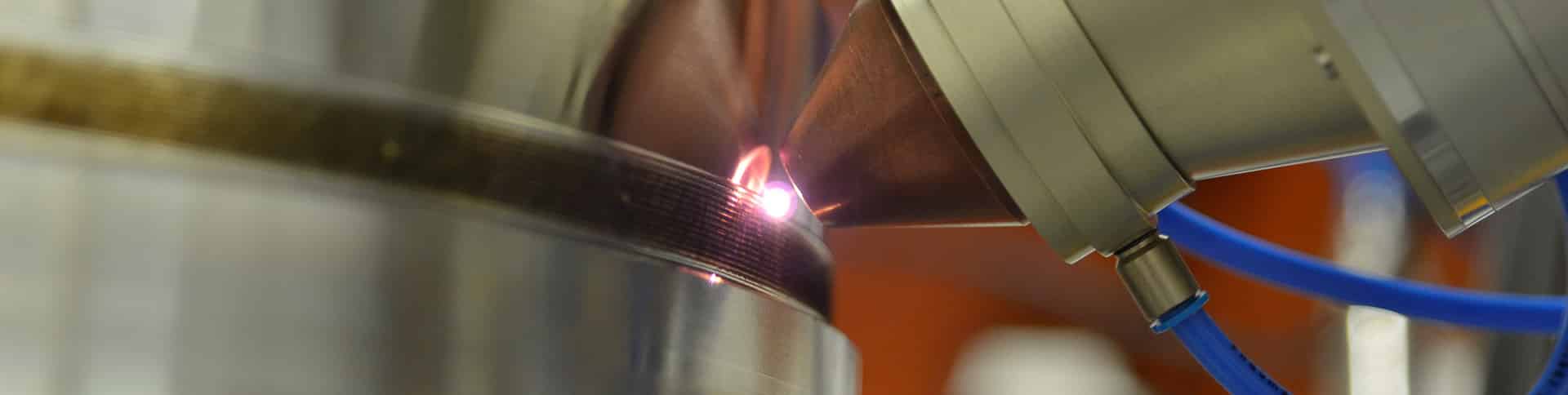

3D generation or additive manufacturing has the potential to revolutionize the design rules and manufacturing processes which have been in practice so far. The rules and processes enable generating components with completely new design, functionality, materials, material composites and customization. We deal with generative manufacturing by means of laser metal deposition. In contrast to the powder bed-based generative technologies, laser metal deposition allows “real 3D shaping” in different spatial directions of the component’s coordinate system by swiveling and rotating the process head or the workpiece. At the same time, significantly higher build-up rates can be achieved, partly even with different materials on one component.

The videos of this process can also be found on YouTube:

The information about the ProFocus laser system can be found in our flyer.