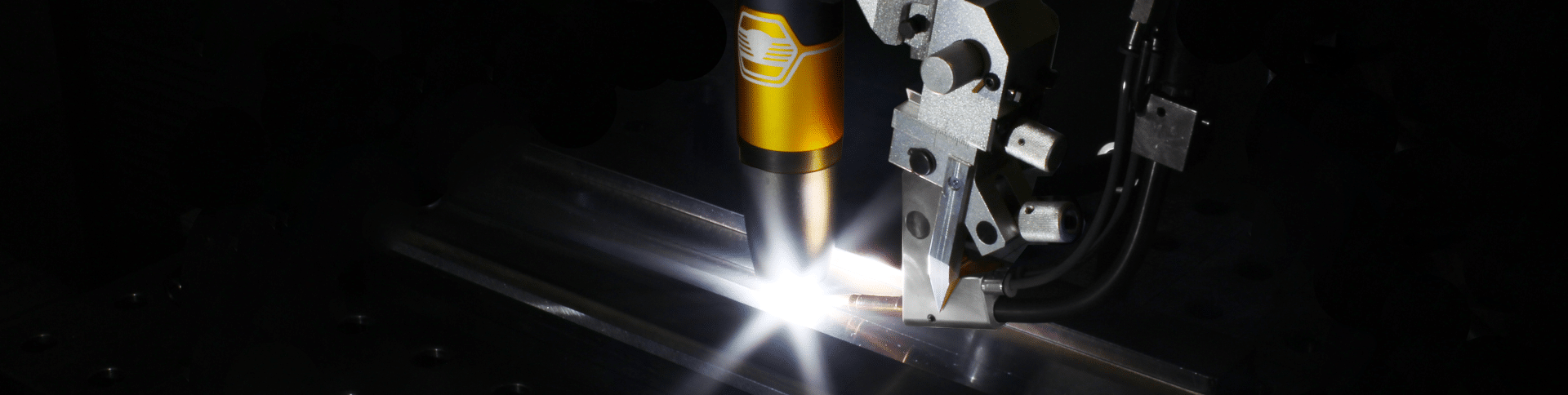

InFocus Pluspole

InFocus Pluspole means next generation in aluminium welding. The TIG process (DC-EP) operated in the plus pole exclusively and enables the high productivity of MIG welding with the usual seam quality of TIG welding. The aluminium surface is continuously cleaned from the disturbing oxide layer by the cathodic arc attachment. The extreme load capacity of the torch and its electrodes with up to 450A (100%ED) enable single-layer welding of sheet thicknesses up to 8 mm without the need for weld seam preparation. The clean saw cut is sufficient.