InFocus

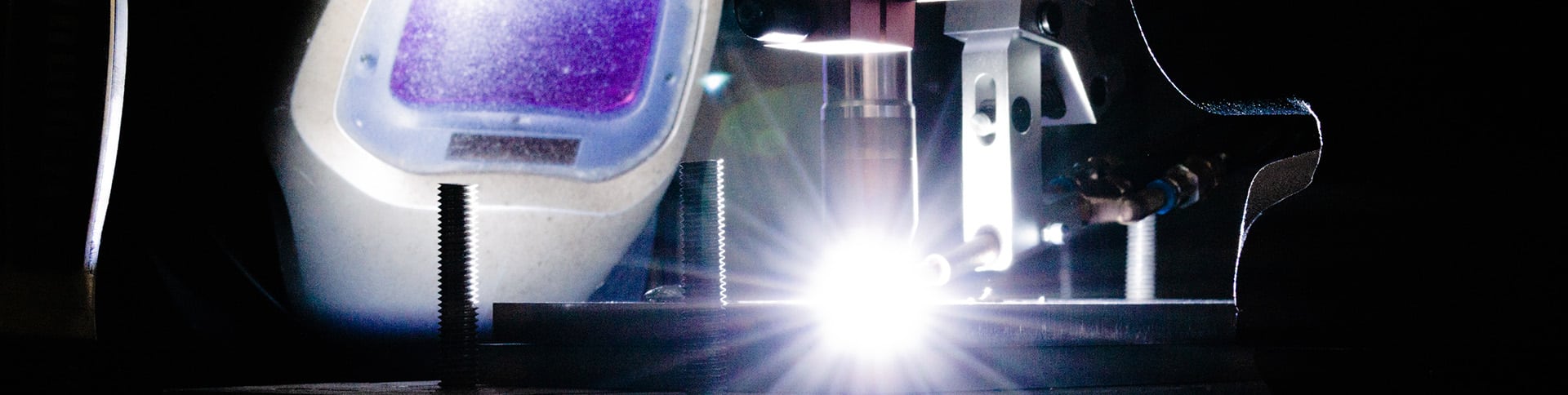

InFocus is a TIG high-performance technology developed by Kjellberg Finsterwalde with a particularly powerful, precise and stable arc. Based on the patented cathode design and optimized cooling, the arc is focused on the cathode tip, which results in an increase in arc stability and welding penetration depth. InFocus is available in 2 torch variants by standard; special torches are available on request.

The TIG high-performance torch InFocus 1000 gets to the heart of full InFocus performance. With a load capacity of up to 1000 A and an absolutely concentrated arc, it proves its unique capabilities for taphole applications and for precision welding with required high arc stability as well. The screwed-in electrodes are optimally cooled by the patented torch design, thus ensuring fast changeover, TCP-accurate workflow and excellent arc characteristics. InFocus 1000 is used to produce single-layered tap hole welds of up to 10 mm. However, the torch is also used for very fast welding tasks on thin-walled, continuously running linear welding systems, for which the high energy density of the arc is crucial.

The InFocus 500 high-power TIG torch, with its compact design and excellent electrode cooling, is the unbeatable tool for an extremely stable arc with limited accessibility. With a diameter of only 20 mm and a torch length to the hose assembly of 200 mm, a welding current of up to 500 A can be implemented. The torch is primarily used for robot-guided tasks on flanges or components with similarly limited accessibility. The InFocus torches and other product components are distributed by Kjellberg Schweißtechnik – the OSCAR team will be happy to consult you.