Services

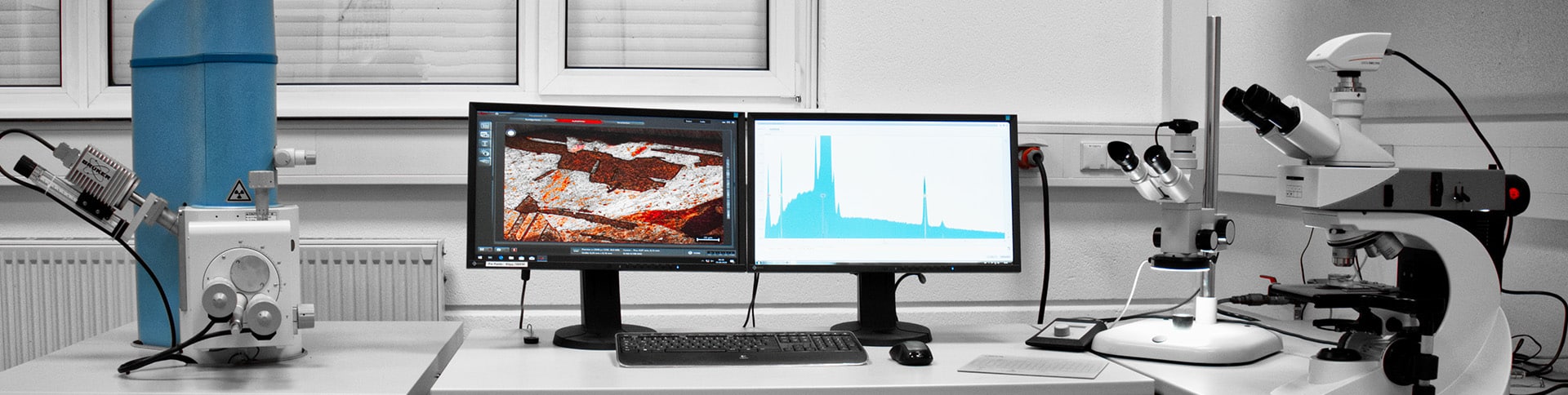

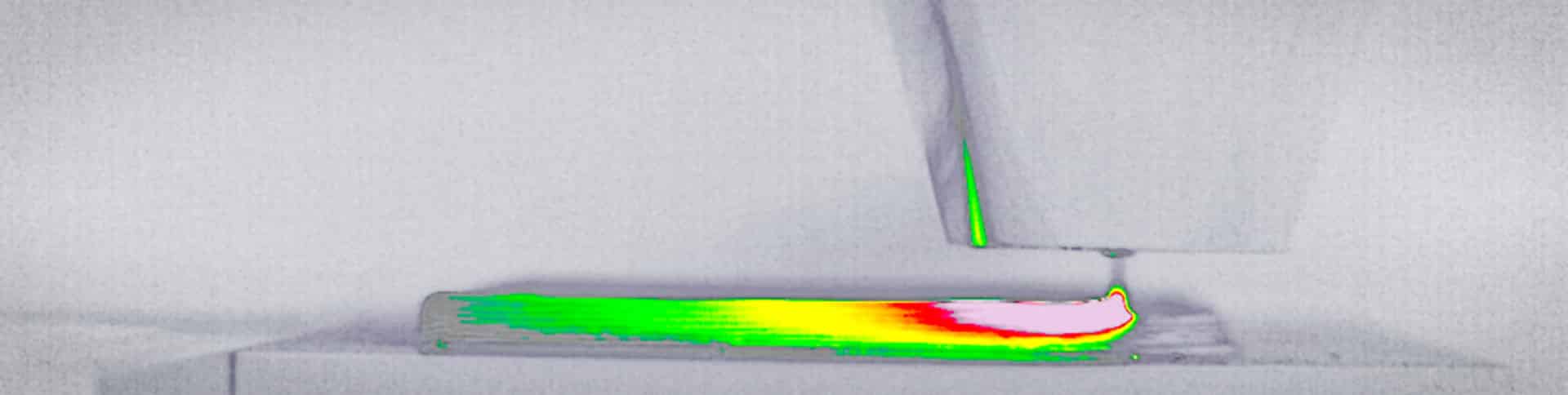

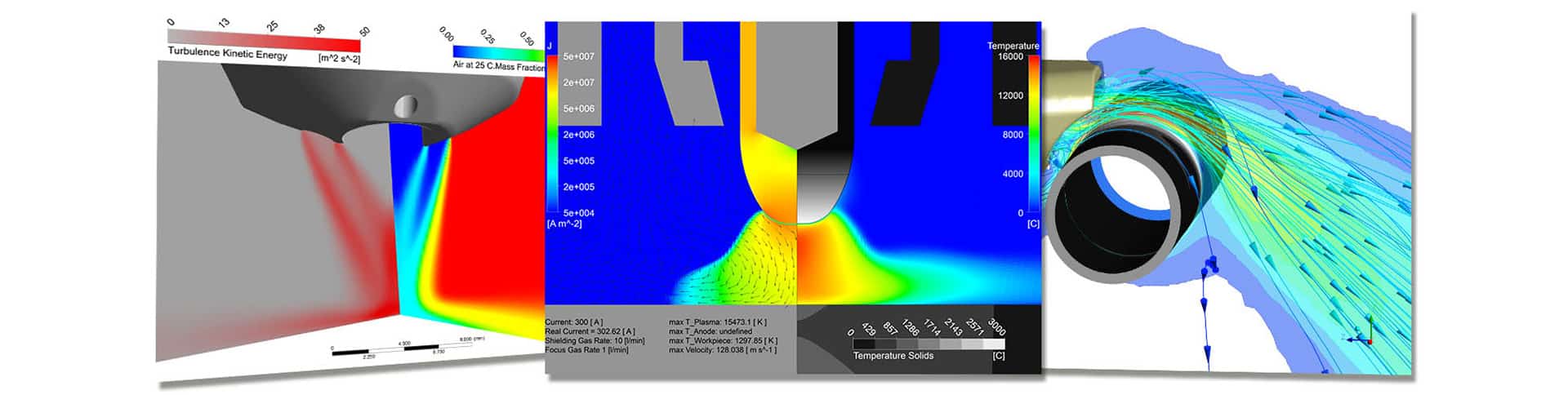

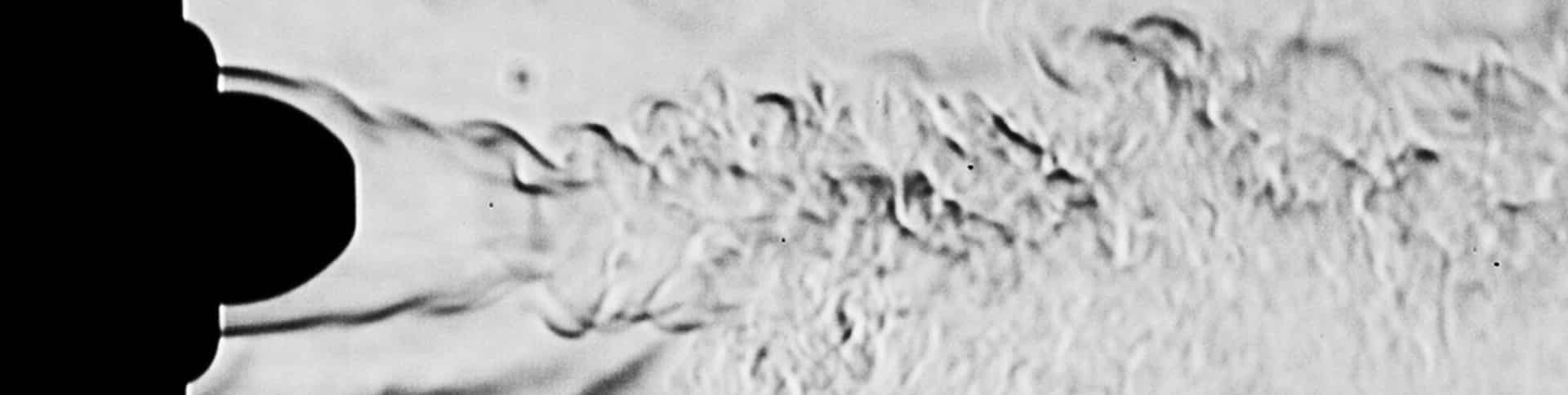

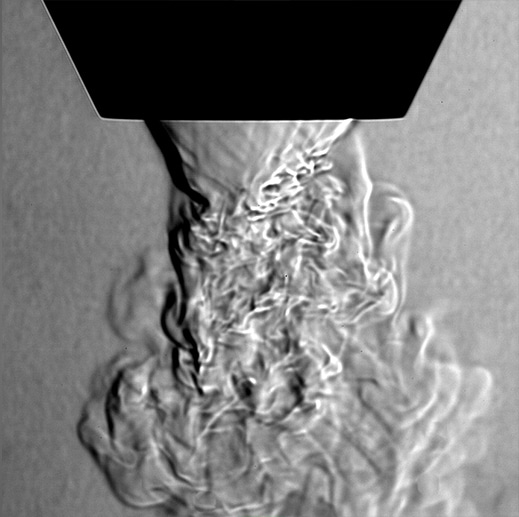

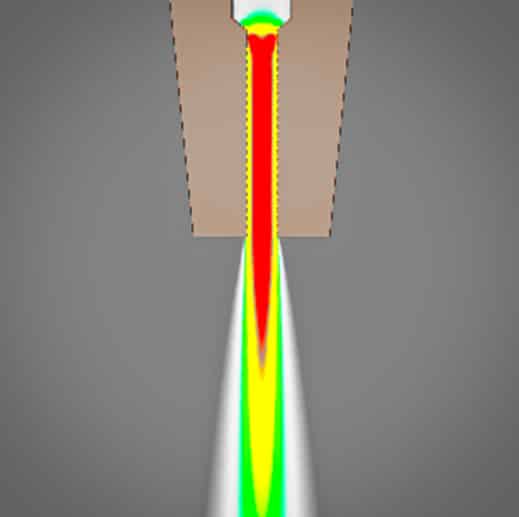

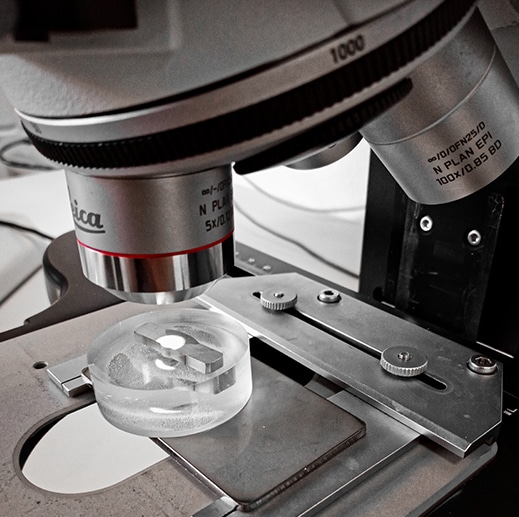

We offer you services in the field of materials characterization and metallography as well as flow and process visualization. We carry out technology and feasibility studies on your components and realize individual technology solutions in cooperation or as contract research.