Flow Analysis

Powerful methods for flow visualization

Currents significantly determine cutting and welding processes. When cutting, the quality of the cutting free jet is decisive for the cutting result. While welding, the quality of the shielding gas flow determines weld seam irregularities, such as pores, annealing colours and the flow and flow behavior of the melt. Therefore, At OSCAR PLT, we use powerful flow visualization methods to design welding heads and to optimize processes. The test rigs are designed for mobile use and can therefore also be used in the customer’s production environment or in the test rigs of partners. The following methods are offered:

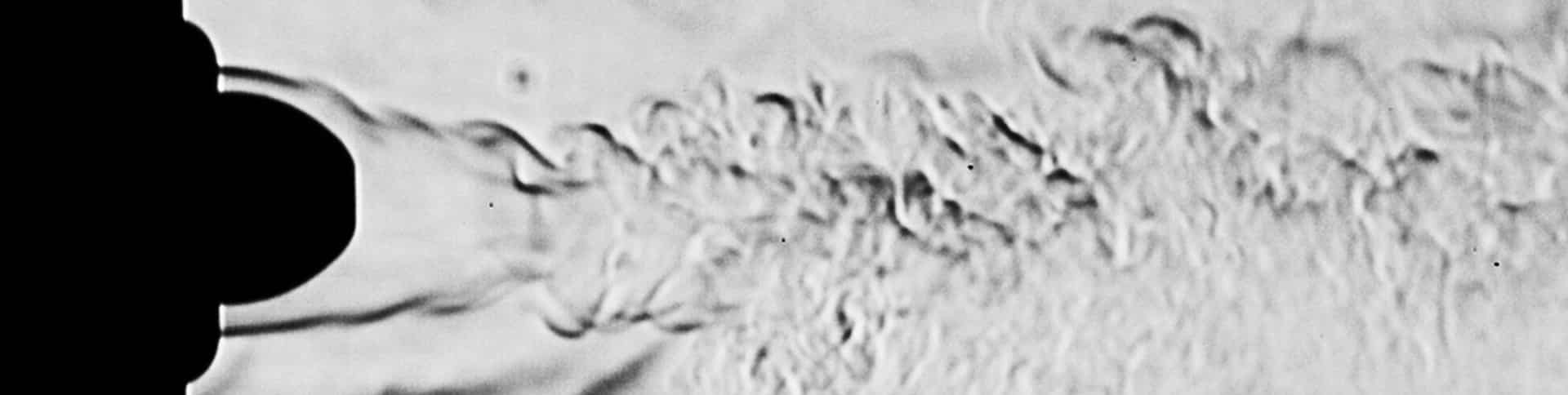

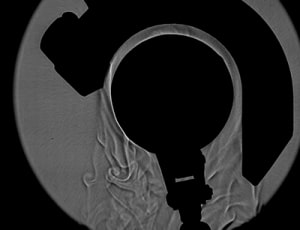

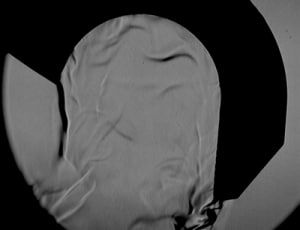

Schlieren measurement is an established method of flow analysis. Further developments in the field of illumination, optical setup and camera technology today enable images of enormous quality. In order to compress information, statistical information is generated from image sequences in the post-processing stage, and structures in the images are specifically set apart from the mean values. Our expertise ensures the analysis results from the measurement setup to the evaluation and discussion of results. The oxygen measurement is used for the spatially resolved determination of the shielding gas coverage, and is particularly relevant in the process of qualifying the welding torches and laser processing heads. In contrast to the Schlieren method, it enables quantitative results via a measuring surface (2D plot) or the radius (line scan) of the shielding gas nozzle. The method is applicable without, but in principle also with, electric arc.