Products

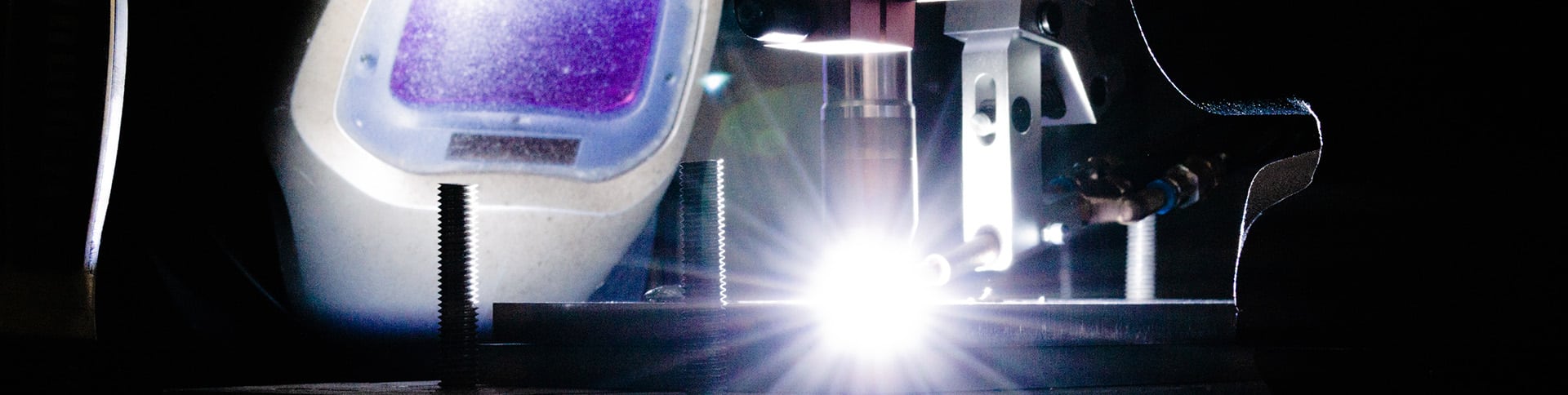

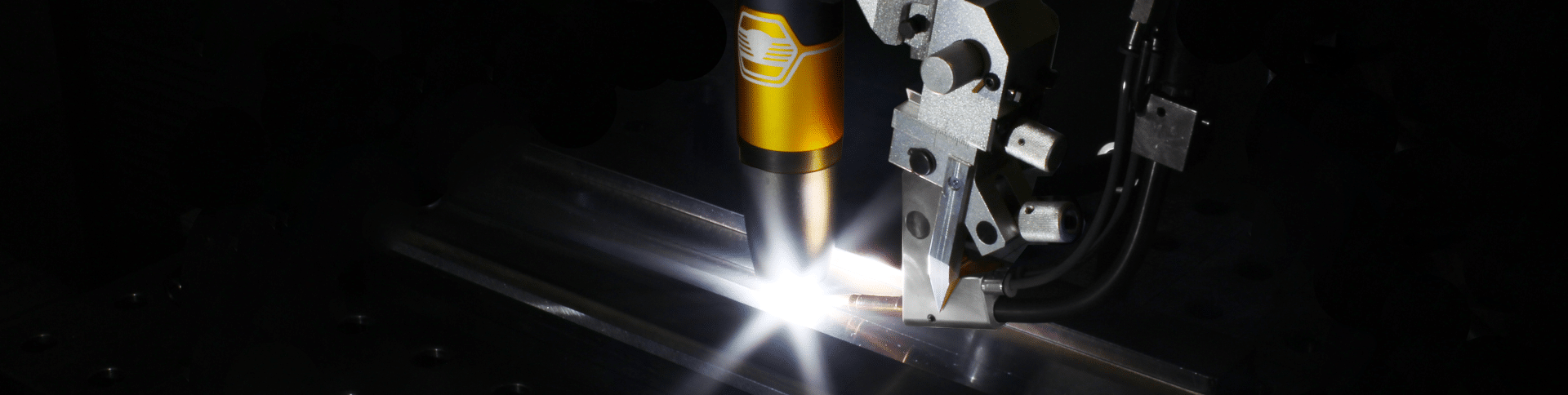

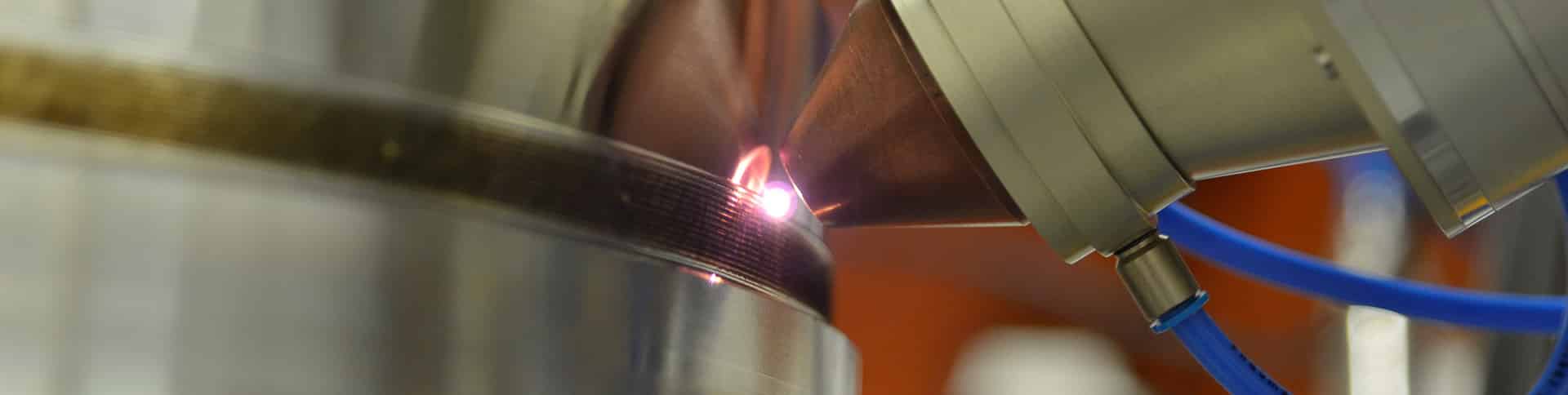

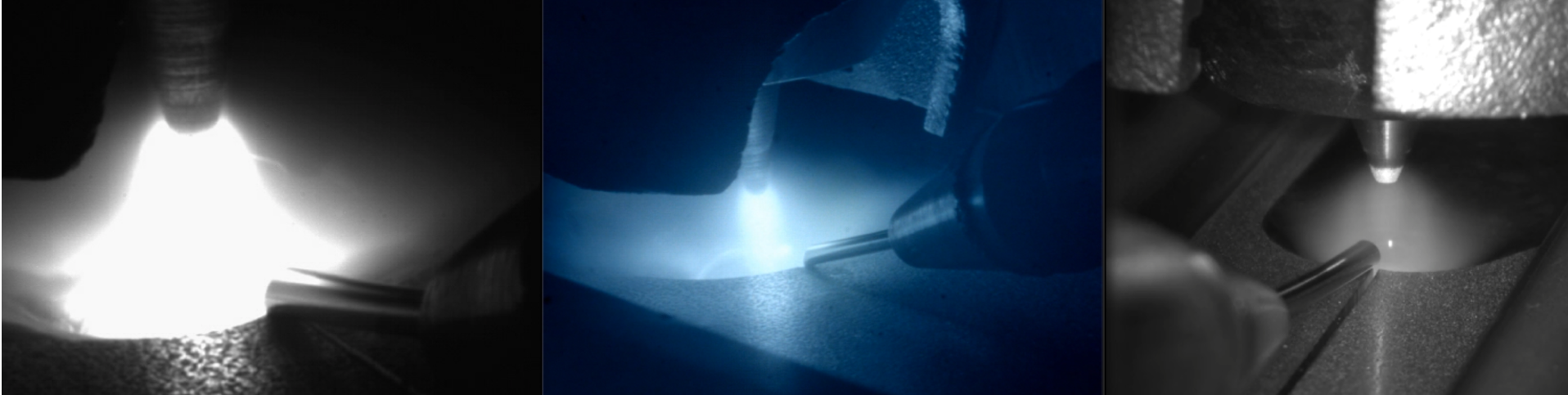

OSCAR PLT GmbH offers you products from the areas of arc welding and additive manufacturing, which are developed, tested and successfully used in industry and research through the many years of experience of our process experts and development engineers.