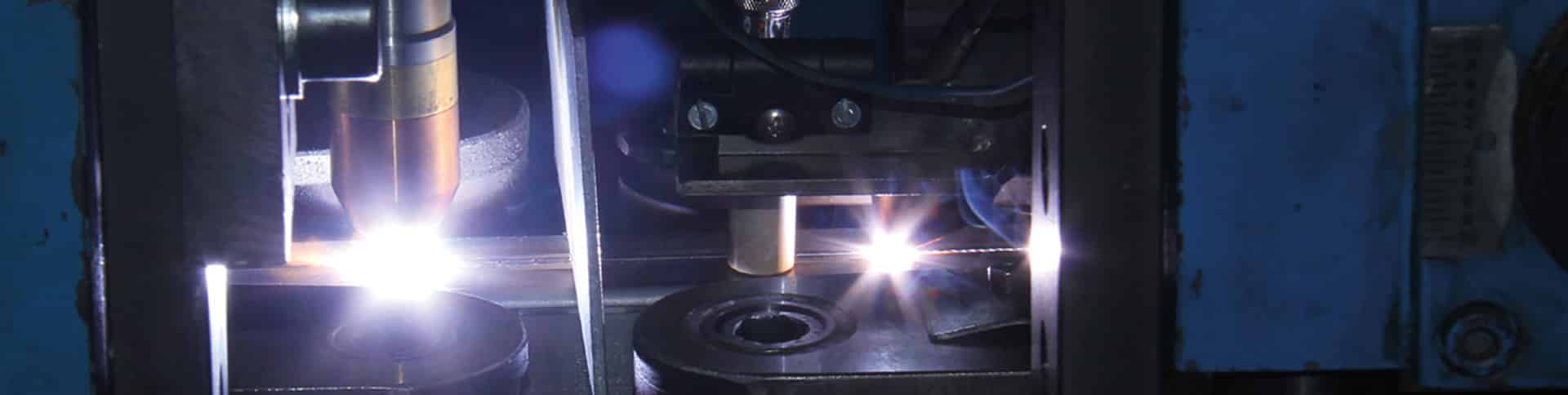

Welding

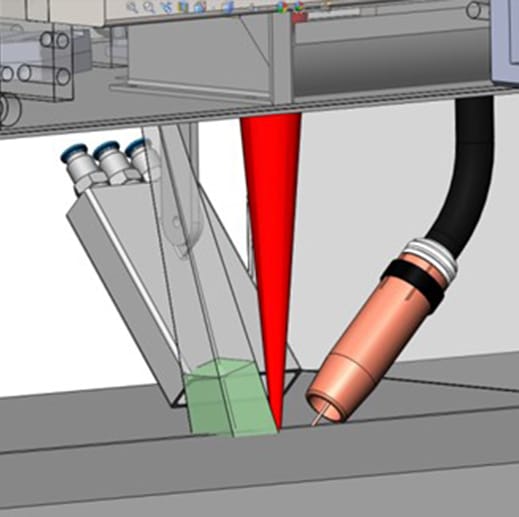

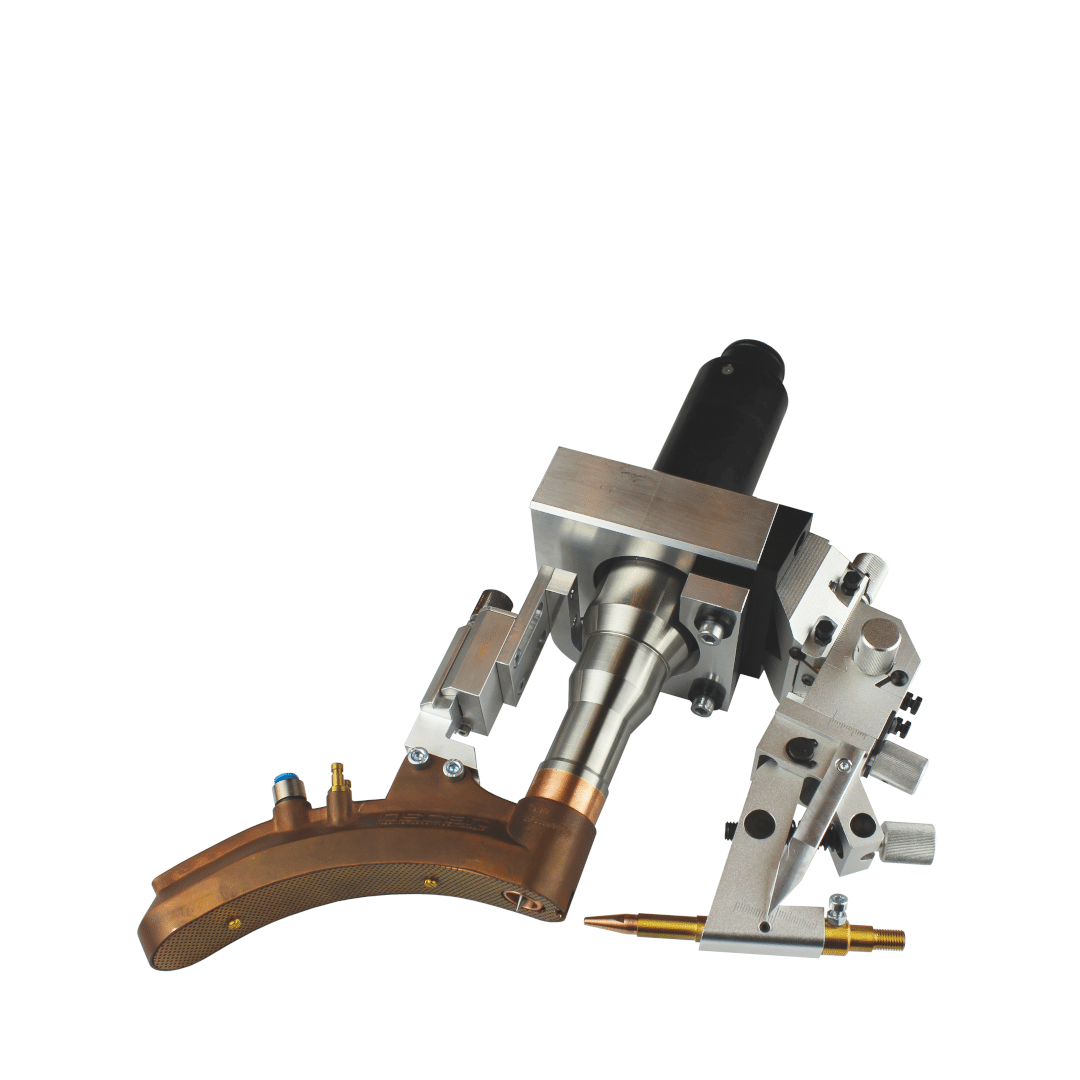

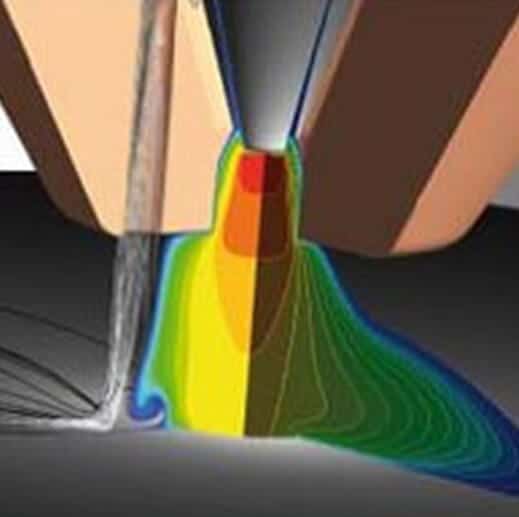

Welding torch as a technology demonstrator

As a research company, we specialize in automated laser and arc welding processes. The main focus is on high-performance TIG technologies for ferrous and non-ferrous metals.

The torches which we have developed are the technology demonstrators of the InFocus and ARCLINE® PP high-performance processes. They stand for the highest quality, productivity and robustness.