Powerful premiere in Berlin: Fraunhofer IPK invests in WLAM with ProFocus

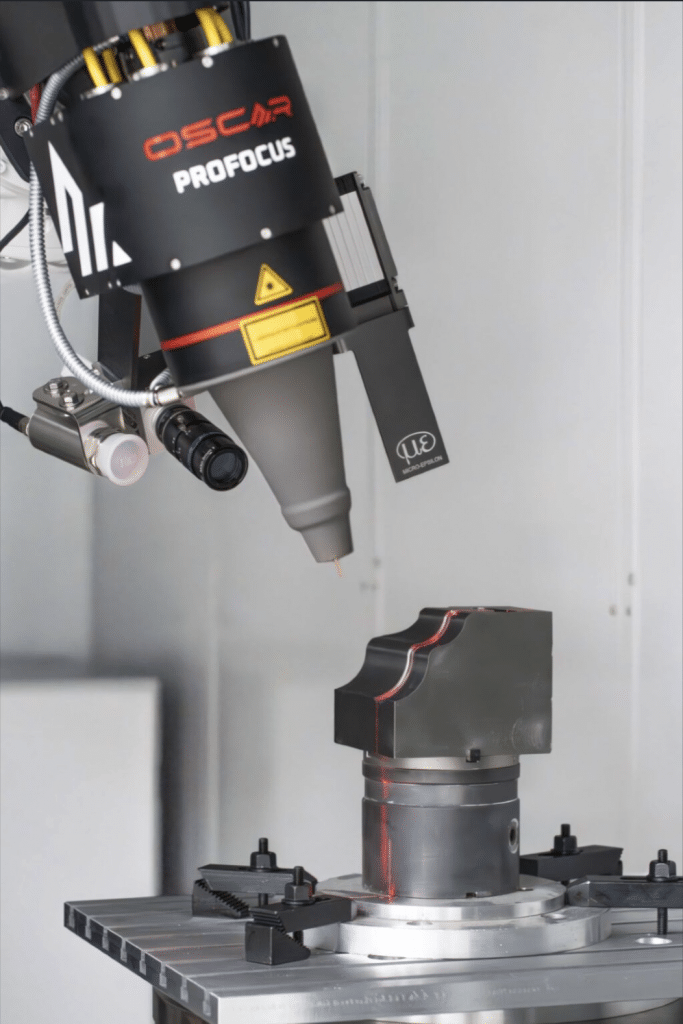

With the successful commissioning of a ProFocus LaserCell at the Fraunhofer Institute for Production Systems and Design Technology (Fraunhofer IPK), a brand-new technology is being launched in the institute’s renowned machine hall. This strategic investment in robot-guided laser metal deposition sends a strong signal to the metalworking industry, as ProFocus’s fully digital process chain, from scanner integration to the final robot program, offers entirely new technical and economic possibilities. The cherry on top? Maximum resource conservation through wire-based deposition, because, unlike the powder process, the entire material remains on the component.

A project of reference for Europe and beyond

Fraunhofer IPK has been researching and developing pioneering processes for the repair and reconditioning of industrial metal components for many years. With the ProFocus LaserCell, a system is now in operation that combines various competencies: scanner-based measurement of damaged areas, automated path planning, and highly stable laser processing with AI-based control and an intuitive HMI. This creates a seamless workflow – from the initial scan of the defective component to the finished, welded workpiece.

The particular strength of this system lies in the seamless integration of the scanner and path planning technologies developed by SKM DCAM. Since the component does not need to be re-clamped, manual planning steps can be minimized and repair strategies can be calculated automatically. This represents a significant advantage in overall efficiency and user-friendliness compared to other solutions currently available on the market.

Laser wire deposition – robust and versatile

A central element of the solution at the IPK is laser wire deposition. This technology is characterized by particularly clean process control and opens up new possibilities for processing materials that were previously considered difficult or impossible to repair. A prime example is cast iron, which was previously considered only partially weldable due to its brittle properties.

The ProFocus LaserCell enables the controlled build-up and repair of such materials. This reduces costs and replacement times for spare parts and significantly extends the service life of machine components – a crucial factor for industries such as mechanical and plant engineering, energy, and transportation technology.

Practical applications

The range of applications for the ProFocus LaserCell is extensive:

Turbine components: Gas and steam turbines are exposed to enormous thermal stress. Even the smallest cracks can reduce efficiency or lead to failure. Laser-based wire deposition allows these damaged areas to be precisely repaired, allowing components to remain in service longer.

Casings and impellers: In chemical and power plants, cavitation and wear often lead to chipping of casings or impellers. Scanner-based repair enables precise repair without having to replace the entire component.

Tools in mechanical engineering: Molds, dies, and various special components are expensive to manufacture and often have complex geometries. Instead of being replaced after a defect, they can now be welded on and reused – with minimal material usage and maximum precision.

Ship and offshore components: Propellers, shaft bearings, or pumps can be precisely repaired despite corrosion and cavitation. This reduces downtime and increases operational capability in maritime operations.

Consistent digitalization as the key

The digitalization of the process chain is more than just a technical detail: In practice, it means maximum transparency, efficiency, and simplified work for the operator. Every processing step is documented, verified, and traceable.

For users, this means:

- High process reliability through automated planning and execution

- Short lead times thanks to direct integration of scanning, planning, and the welding process

- Reproducibility even with complex components or changing batches

The system at Fraunhofer IPK thus establishes a model for what repair and remanufacturing processes could look like in the future – standardized, digitalized, and sustainable.

Profitable and Sustainable Welding

Resource-efficient metal component repair is becoming increasingly important in light of rising raw material prices and growing environmental demands. Wire laser cladding is a key technology in this area: Instead of scrapping defective components, they can be reprocessed and reused. This not only saves costs and time but also avoids unnecessary CO₂ emissions from energy-intensive new production. Recent history has also shown that reduced dependence on global supply chains is a decisive strategic advantage.

The successful commissioning of the ProFocus LaserCell at Fraunhofer IPK demonstrates how practically applied research can respond to industrial requirements – and how closely sustainability and competitiveness are linked.

A showcase for the metalworking industry

The historic machine hall at Fraunhofer IPK is not only a research environment, but also a showcase for industry. Companies from the fields of mechanical engineering, energy supply, transportation technology, and aerospace now have the opportunity to experience the performance of the new LaserCell under realistic conditions.

Interested companies can expect a well-thought-out, comprehensive process: from the initial digital scan through automated path planning to precise welding – live and reproducible. This allows them to experience how the repair of complex metal components is fundamentally changing through the combination of digital planning and robust wire deposition welding.

Conclusion: laser wire deposition is key to industrial repair welding

The commissioning of the ProFocus LaserCell at Fraunhofer IPK is a visible sign of how digital process chains, modern welding technologies, and sustainable strategies intertwine. For the industry, this offers a practical reference project that will have a lasting impact on the future of industrial wire deposition welding.

👉 Seize the opportunity to take your repair and manufacturing processes to the next level. With the ProFocus LaserCell and OSCAR-PLT technologies, you can increase efficiency, precision, and sustainability.

👉 Contact us now and secure your lead in the metal processing industry.