Our products for your success

OSCAR-PLT develops profitable solutions for companies that want to fully utilise the potential of metal 3D printing and additive repair. Our products are based on years of research and development as well as successful cooperations with leading companies in a variety of industries. Our equipment and systems reliably deliver excellent quality, even under the most challenging of conditions.

The proven metal 3D printing system that started it all. A versatile technology that enables unmanned, direction-independent welding - with both wire and powder LMD (Laser Metal Deposition).

This compact version of our pioneering laser head weighs just 6 kilograms and still brings all the advantages of the ProFocus technology, enabling new applications and geometries.

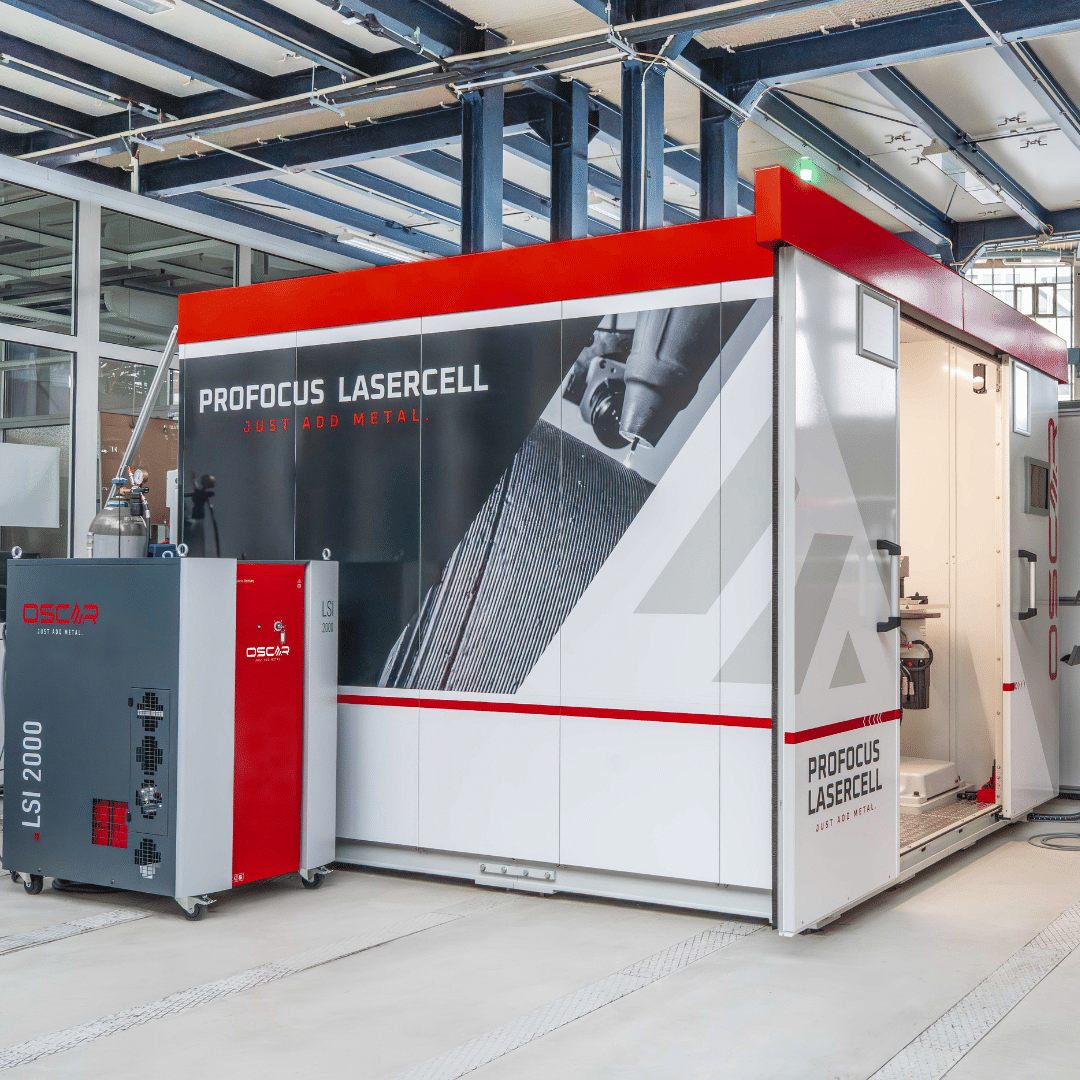

The compact version of our laser cell for production environments with small to medium-sized components. It combines the quality and efficiency of the ProFocus laser cell with a particularly compact footprint and easy transportability.

Revolutionise your metal 3D printing with our complete solution, the ProFocus LaserCell. Turnkey and customised to improve your production and expand your company's economic opportunities.

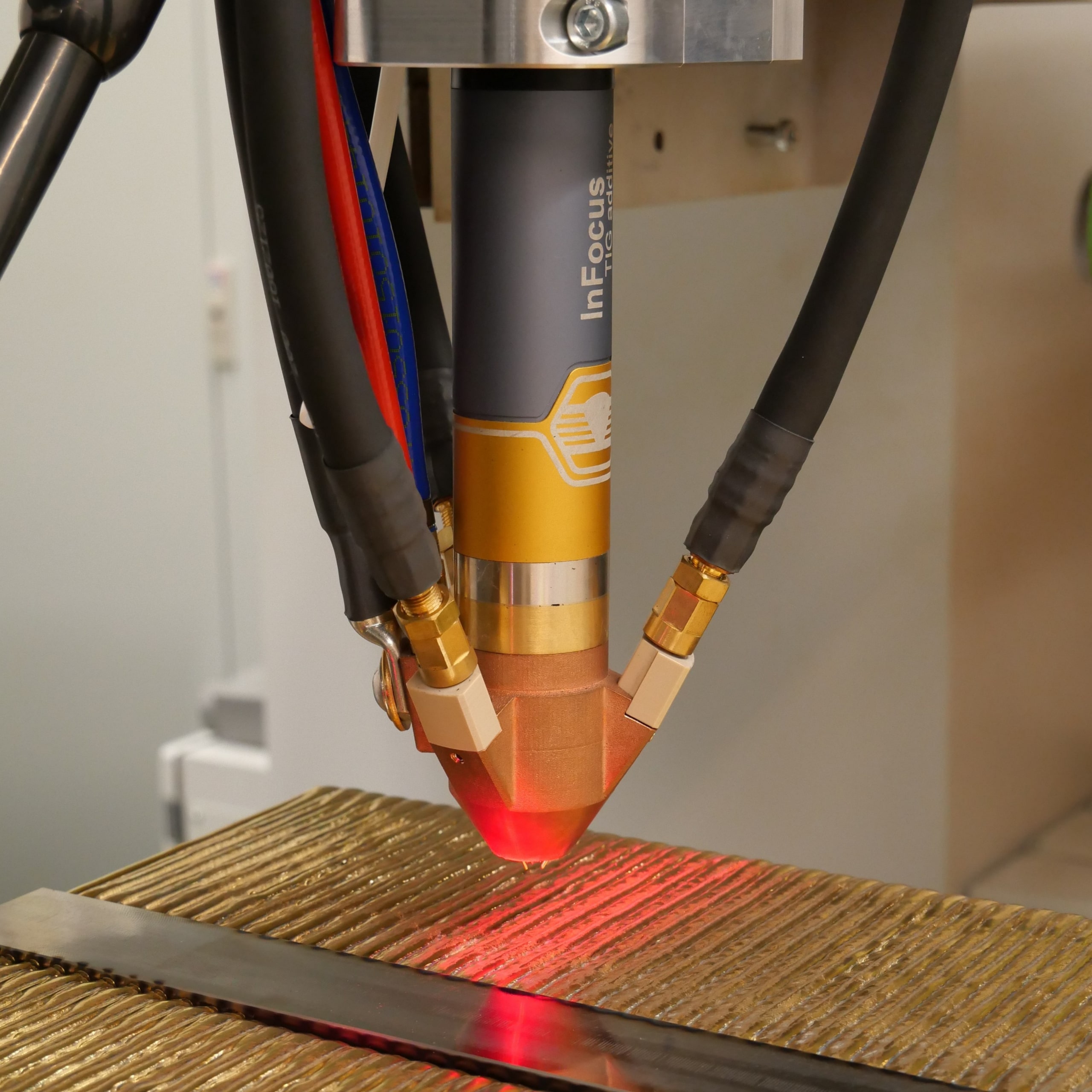

3D generating and coating with high deposition rates. The combination of proven components from TIG welding with the additive expertise of OSCAR PLT.

InFocus and InFocus Pluspoles stand for maximum productivity, quality, and robustness in automated high-performance welding.

The perfect weld seam - a goal that can only be achieved with the right gas protection. Our additively manufactured gas nozzles are individually designed for specific welding tasks - and save your company time and money.

High-quality process monitoring is the key to success.We analyse your production environment and provide you with the right camera for your individual process.

Do you have questions about our company, our products or our services? Then you've come to the right place.

Depending on the component properties, we can apply targeted coating in the interior area up to a distance of 100 mm based on different available focus lengths.

Our systems primarily enable the processing of workpiece surfaces or the construction of entire 3D component geometries. For classic joint welding or hardening, we are happy to recommend partners from our network.

Deposition welding with wire is the most material-efficient and safest laser technology. It is characterised by high availability, cost efficiency, easy handling and certified filler metal quality. It also minimises material loss and is harmless to health.

You are currently viewing a placeholder content from Brevo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from Turnstile to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information