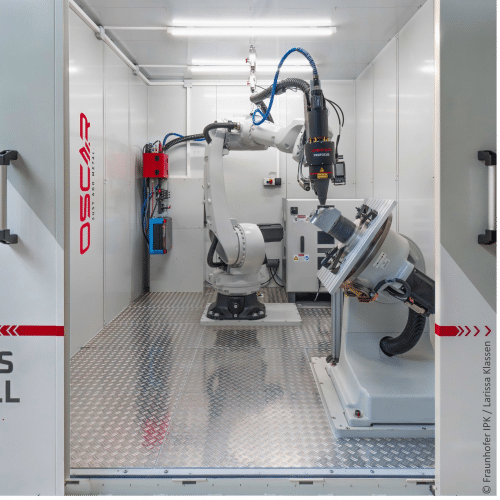

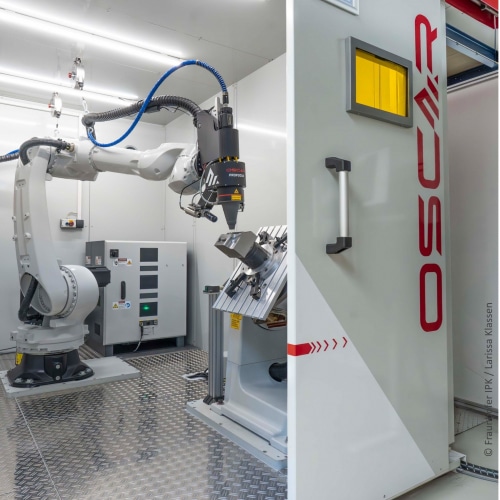

Metal 3D printing system

Increase your production capacity with the ProFocus LaserCell, the customised, turnkey metal 3D printing solution from OSCAR-PLT. Each system is customised to the specific needs of the customer. Equipped with a 6-axis robot and advanced process control, the LaserCell enables precise and flexible production for components of any size and is also mobile. Innovative functions such as Path Planning, StartControl for automatic part recognition, WireWatcher to prevent wire breakage, HeightControl for automatic height adjustment and integrated HDR process monitoring with temperature detection guarantee maximum quality and efficiency. With Kjellberg’s expertise, this system offers a reliable, high-performance complete solution.

The ProFocus LaserCell allows our customers to get started with additive manufacturing in record time.Discover the production of tomorrow today.

The simple operation of the laser cell is one of the great strengths of this system.Of course, OSCAR-PLT is also at your side with training and agile technical support.

The modular ProFocus system can be individually upgraded and converted.Popular system upgrades include functions such as height control, temperature detection and the OSCAR gas control kit.

Are you looking for a reliable system for unmanned, direction-independent welding? Then ProFocus is the right choice for you. This reliable system technology enables absolute process control and near-net-shape production.

Do you have questions about our company, our products or our services? Then you've come to the right place.

The dimensions of our cameras are very small. However, if it is still too small for the process display, we can offer you solutions to make the best possible use of the installation space.

Depending on the angle and position of the camera, it is possible to observe the process. In addition, a cut-out or a sight glass can be inserted into the trailing gas nozzle if a larger viewing area is required.

Our drag gas nozzles are not wear parts, but are designed for continuous operation. There are replaceable wear parts in the nozzle body that can be replaced if they become heavily stained (e.g. by welding spatter).

The proven metal 3D printing system that started it all. A versatile technology that enables unmanned, direction-independent welding - with both wire and powder LMD (Laser Metal Deposition).

This compact version of our pioneering laser head weighs just 6 kilograms and still brings all the advantages of the ProFocus technology, enabling new applications and geometries.

The compact version of our laser cell for production environments with small to medium-sized components. It combines the quality and efficiency of the ProFocus laser cell with a particularly compact footprint and easy transportability.

You are currently viewing a placeholder content from Brevo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from Turnstile to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information