Metal 3D-printing with high deposition rates

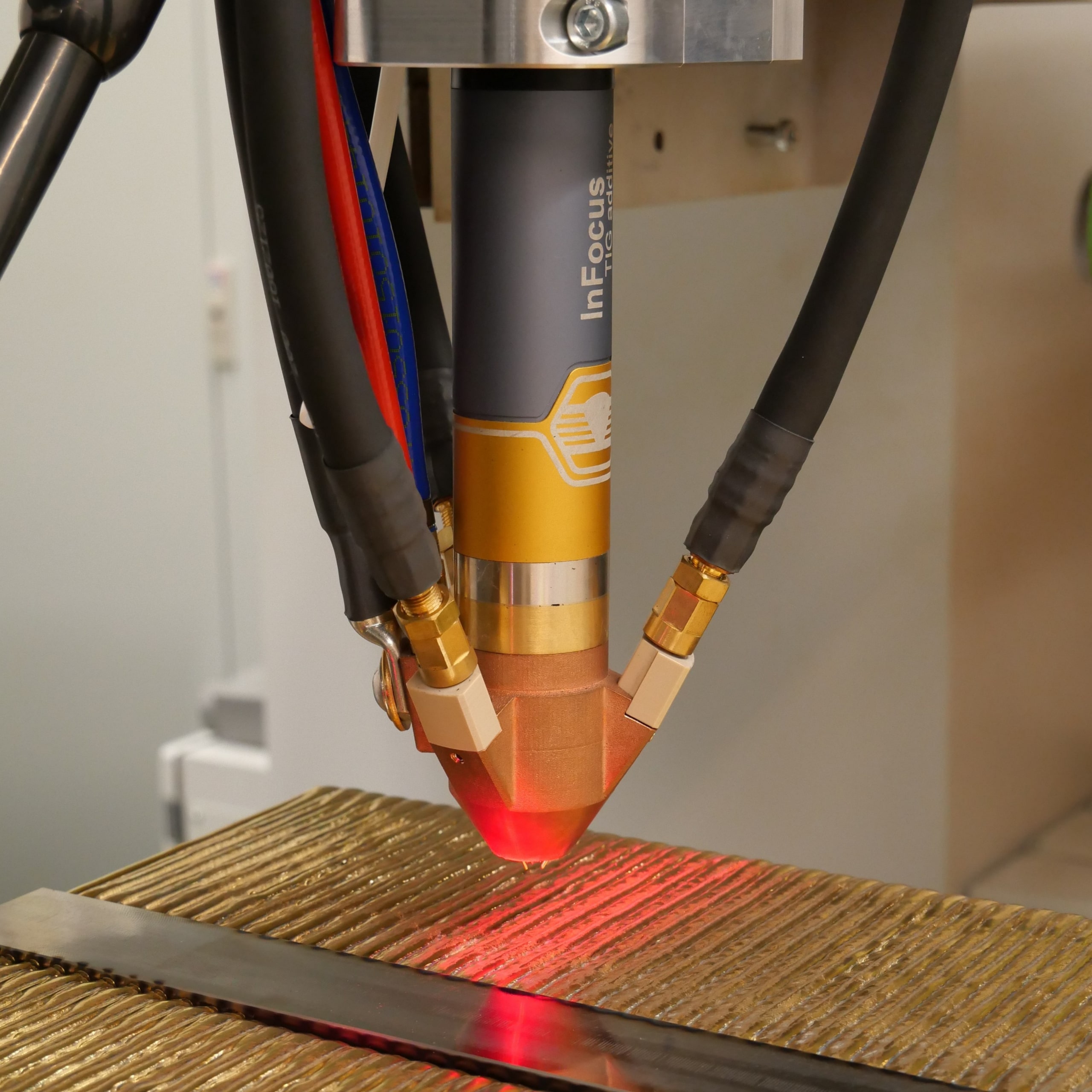

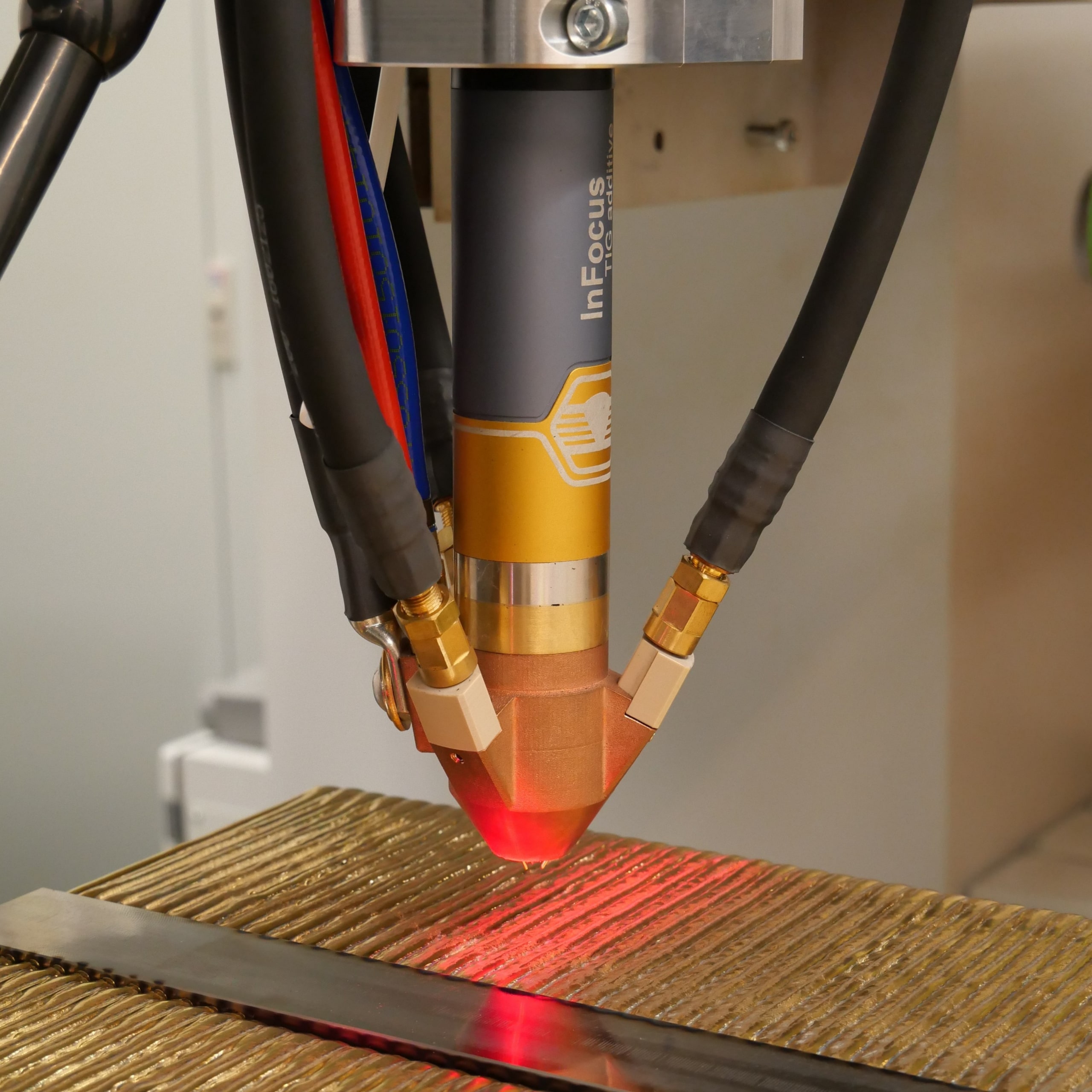

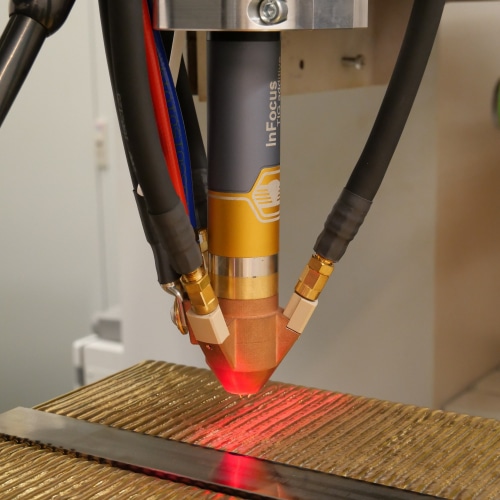

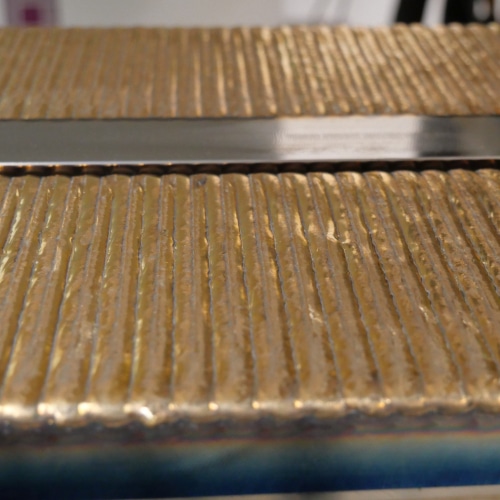

The TIG-3D process head with Kjellberg InFocus torch enables precise build-up welding and additive manufacturing with high process reliability. The triple wire feed with hot wire option allows deposition rates of up to 12kg/h for large-volume structures or high-performance multi-layer coatings. Integrated sensors, assistance systems, automatic height control, and camera-based process monitoring ensure reproducible, automated production. The compact system is designed for integration into robot and multi-axis systems and is ideal for demanding industrial applications.

The highest melting rates are achieved by melting three wires in parallel.

The ease of use of the OSCAR HMI and the assistance functions allow for a quick introduction to TIG 3D technology.

The welding system can be customized to suit your specific applications. Easy integration into robot and machine systems enables flexible working with TIG 3D technology.

Would you like to apply or generate coatings automatically and highly efficiently? Then the innovative WIG 3D system with integrated process control is the solution for you.

Do you have questions about our company, our products or our services? Then you've come to the right place.

Yes, we offer demonstrations of our camera models in your production environment. Please contact us to make an appointment, we would be happy to show you our welding cameras in action.

Depending on the angle and position of the camera, it is possible to observe the process. In addition, a cut-out or a sight glass can be inserted into the trailing gas nozzle if a larger viewing area is required.

Depending on the size of the trailing gas nozzle, the gas consumption is approximately between 20 and 40 litres/min. With this amount of gas, a much larger area can be covered on the component than is possible, for example, with welding torches with large gas lenses.

The proven metal 3D printing system that started it all. A versatile technology that enables unmanned, direction-independent welding - with both wire and powder LMD (Laser Metal Deposition).

This compact version of our pioneering laser head weighs just 6 kilograms and still brings all the advantages of the ProFocus technology, enabling new applications and geometries.

The compact version of our laser cell for production environments with small to medium-sized components. It combines the quality and efficiency of the ProFocus laser cell with a particularly compact footprint and easy transportability.

You are currently viewing a placeholder content from Brevo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from Turnstile to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information